Project Overview

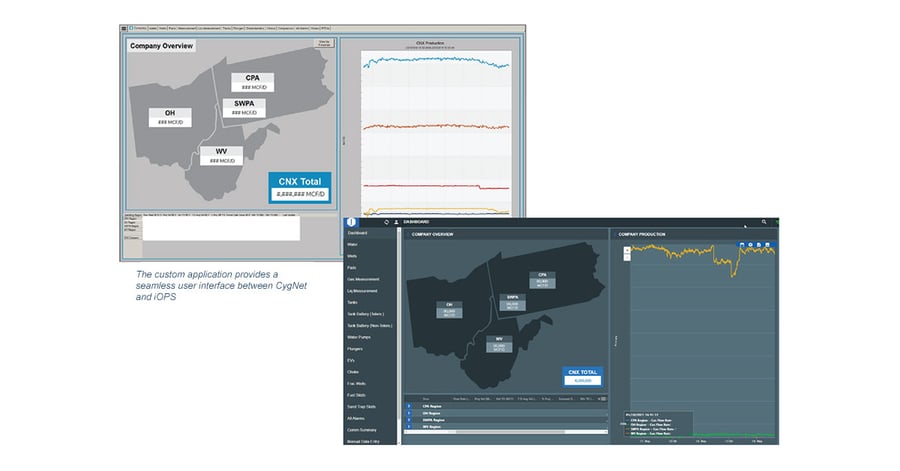

CNX Resources, a premiere independent oil, shale gas exploration and production company with operations centered in the Appalachian Basin, enlisted TIGA as a trusted partner to align and develop their use of technology with the desired business outcomes. The solution deployed allowed CNX Resources to spend less time on alarming and focus on more critical items. In turn, it assisted in CNX Resources’ strategic initiative to grow without scaling - and to lead the basin in lease operating expenses.

“Partnering with TIGA, we have been able to develop custom apps and feature sets that service very unique operational needs. TIGA has delivered these on time and budget and enabled our operations workforce to be more flexible, nimble, productive, all while reducing operating costs.” - Ravi Srivastava, VP of Data Operations and OT CNX Resources

Business/Industry Problem

CNX Resources was seeking more insight into production exceptions that would proactively address field technicians and the remote operating center. There was limited access to the facilities list while offline, as well as the current values of each facility, which required a Manual Synchronization of the Field Data. CNX Resources wanted to enable the field/remote work force to have higher visibility into production and be able to prioritize value through an alarm prioritization, as well as allow the Control Room Operators to make actionable insights through a mobile platform.

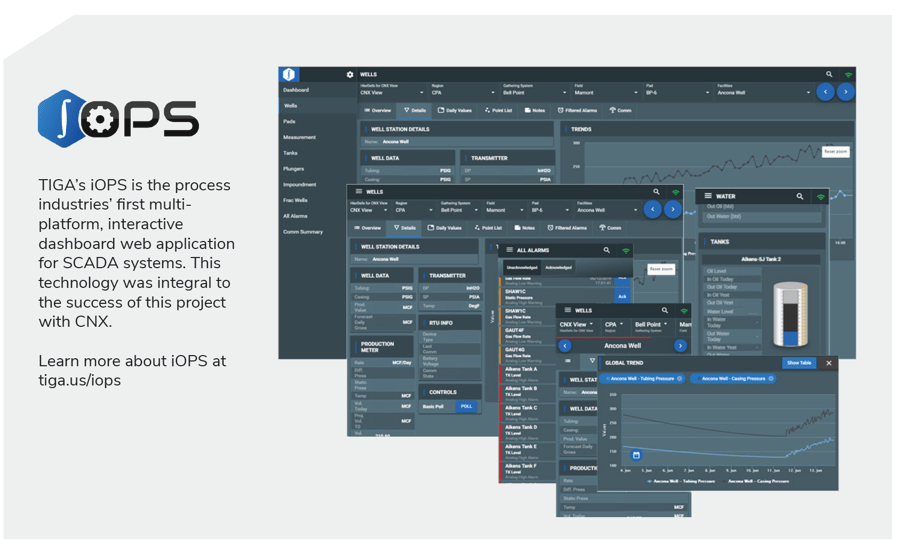

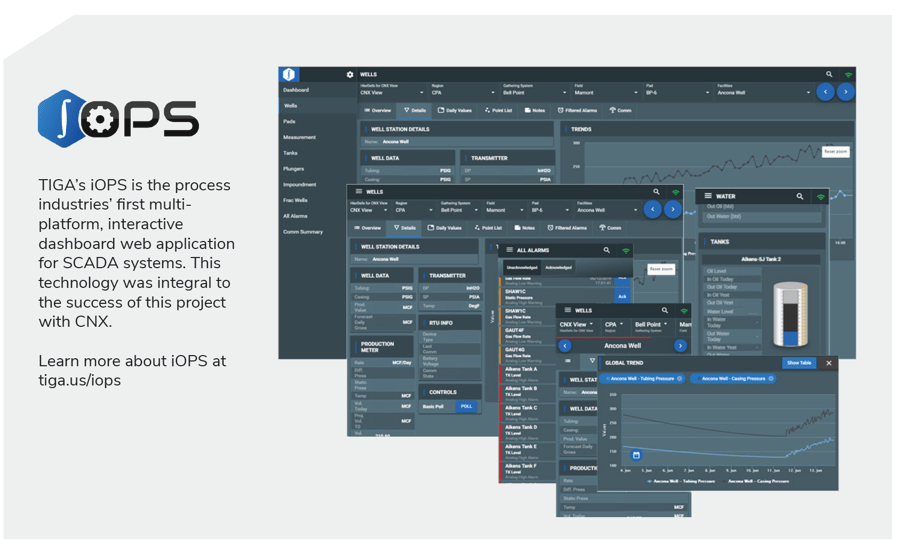

To continue being a leader in the Basin, CNX Resources wanted to, “leverage technology to provide a competitive edge,” stated CNX Resources’ Product Manager of Operational Technology, Michael Yoho. This required CNX Resources to upgrade to a remote, flexible, cost effective iOps system that is able to provide features that redefine business processes, and enable end users with data and control functionality. The previous operational system was unable to accommodate CNX Resources’ field workers with situational awareness.

TIGA Solution

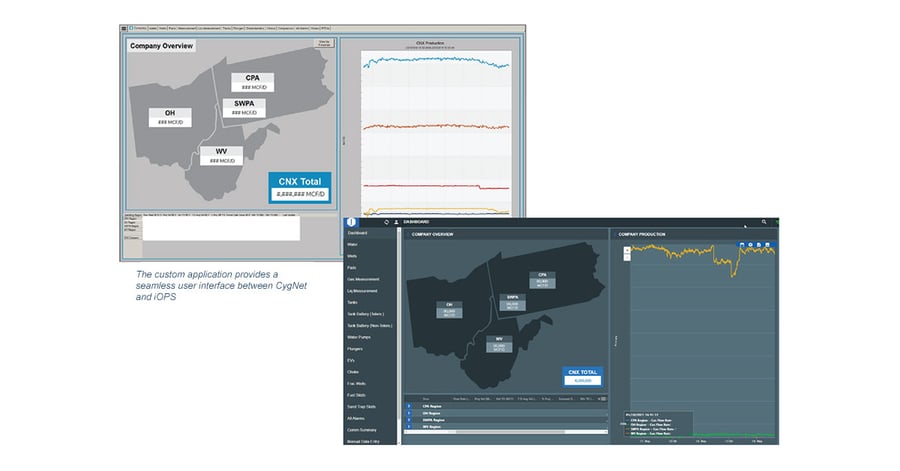

TIGA’s combined track record of building robust customized solutions for many oil and gas companies along with expertise with emerging technologies, SCADA applications and developing custom solutions integrated with off-the-shelf products, HTML5 application, and offline capable web-based solutions, were the reasons CNX Resources chose to partner with TIGA for these projects.

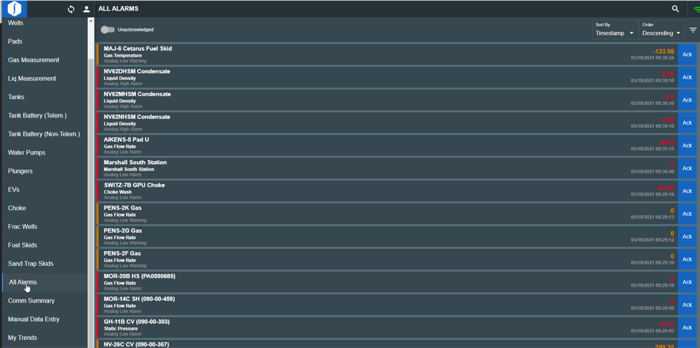

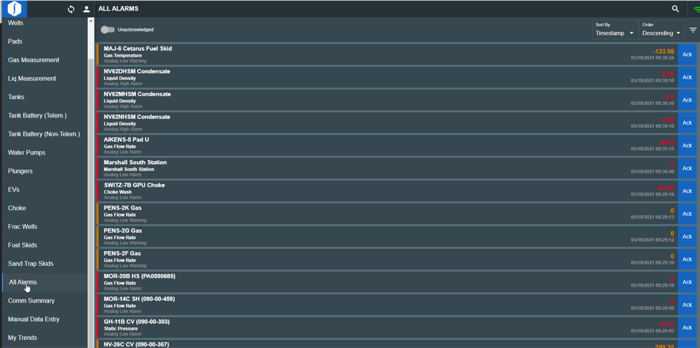

TIGA and CNX Resources partnered to develop an innovative means to manage “cause and effect” alarming. This project standardized and centralized alarming and process variables from several control types into one operator friendly interface. Syncing alarming values if changes were made in the field or in the office. TIGA redesigned the HMI to have a more “top-down” effect that allows CNX Resources’ controllers the ability to change alarm set points from the remote operating center and from the field.

Alarm Rationalization point priority, giving the ability to change alarm setpoints remotely.

Level readings were placed into CNX Resources’ tanks, reading the amount of salt water being pumped, and utilizing CygNet and iOps to provide situational awareness from the facilities to CNX Resources’ remote operating center. These improvements not only lowered trucking costs, but also helped CNX take 65,000 water trucks off the road in 2020. The controllers can create a water hauler’s schedule, based on tank location, production, and the haulers coming and going.

Along with rationalizing the water hauler’s schedule, the data analytics audits the amount of water disposed and the cost associated with the amount of water being hauled. Rectifying the off-the-shelf mobility solutions, TIGA utilized Google’s Angular HTML5 framework to build a mobile solution responsive to all form factors and consolidated the administrative overhead of having a mobile application and web-view to maintain.

TIGA proceeded to develop a single application with feature sets, instead of having to enter real-time SCADA data and field data capture into two different applications.

TIGA implemented a form that allows users to add and remove entries that then syncs those entries with CygNet when the connection is restored. The latest technology was leveraged through a mobile application that allows lease operator to control aspects of their operations. iOps has allowed CNX Resources to quickly shift from water to gas uplift to cost.

Value Delivered

“Our partnership with TIGA’s research, development and SCADA integration teams yielded us phenomenal results in terms of operational efficiency and automation. TIGA’s commitment to customer service, quality and results oriented culture helped us to deliver solutions seamlessly. They come with both midstream and upstream operational knowledge which is a huge plus. We can count on them anytime.” - Ramesh Lanke, SCADA / Cloud Engineer

CNX Resources was locked into an application that was no longer supported, and TIGA was able to deliver a supported solution driving CNX Resources away from the proprietary solution. By building a single application, multiple platforms are utilized, such as phones and tablets, which reduced the number of applications requiring support.

“With the help of TIGA’s thought leadership and brain trust with technical skills, we have enabled our field workers to have control and make decisions from the field,” states Michael Yoho. This has improved the process of data entry by taking away the time-consuming manual plugins that would not accurately transfer the data to the remote operating center.

“We have also experienced a 79% reduction in well-tending costs since 2016, when we started working with TIGA, which speaks volumes,” continues Michael Yoho.

TIGA’s solution assisted in disentangling the idiosyncrasies of field and pad infrastructure into one common technological ground. Changes can be made from the remote operating center and/or the HMI, triggering the correct alarms and allowing maintenance bypass.

Through TIGA’s implementation of a scalable water platform, alarm rationalization, and iOps solutions, the information being pushed and pulled from the remote operating center and the facilities, allows haulers, field technicians, and controllers the ability to accurately audit production based on data analytics, thus producing cost savings.

“It’s about partnering with someone you trust and someone that is going to provide you a scalable, correct solution. We aren’t just getting TIGA’s Manager of Enterprise Solutions, we are getting everyone at TIGA.” Michael Yoho, Product Manager, CNX Resources