Challenge

A leading Independent Energy Company had an antiquated SCADA system that was unable to meet the growth and potential of its operations and accounting needs. With operations across the state of Texas and Louisiana, their SCADA system needed to be open, flexible, and extensible IoT platform that would be a future-proof ecosystem of technology. Additionally, the organization needed an enterprise SCADA system that their production team could quickly transition into due to the operational changes it was undergoing.

The platform needed to be customized to the company’s needs and manage the systematic changes necessary to run their operations at maximum efficiency while also providing insights into accounting. Manual maintenance at the tag level would not be applicable to the consistent changes the company was experiencing. Notification of changes needed to be identified and alerted quickly and swiftly, to allow optimal time for decision making.

The company preferred a live, mobile platform to complement the desktop SCADA system which allows appropriate response times from every team member in the field and office environment. The mobile platform would need to scale to provide the same overview and detailed information provided on a high-resolution desktop monitor. This made Inductive Automation’s Ignition Perspective the ideal platform as the ideal solution.

Due to the upgrade the SCADA platform, the decision on the polling engine was unsure. The field had a wide variety of device protocols which expanded Ignition’s native driver set. TIGA had to test and help select the correct OPC polling engine to support the client’s updated SCADA platform.

Solution

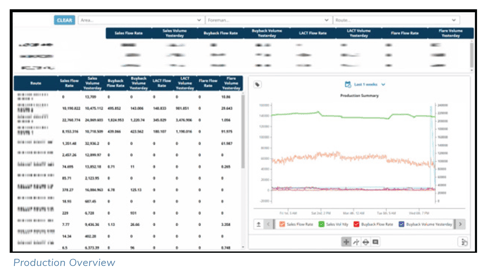

The solution was to deploy a customized enterprise Ignition SCADA system that would provide high-level visual overview, while also allowing users to drill down to more specific detailed data. Using Ignition Perspective, TIGA was able to develop a system that allows users to filter and maintain their filter across the SCADA platform; then used the various screens to determine the best course of action while preserving the selected filters.

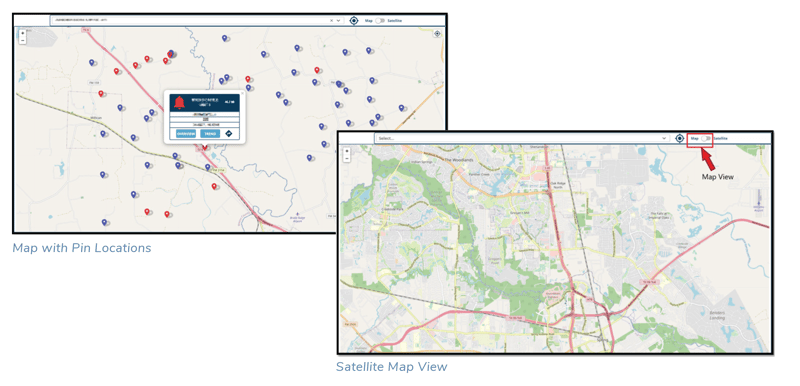

The SCADA system interfaces with Apple Maps and Google Maps applications, allowing mobile users to identify their desired facility and immediately have directions from their current location to the associated facilities’ pins. When using the Map Overview screen, the user can switch from Map view to Satellite view, to provide a real-world top-down view of their facilities’ locations.

The GPS Pins interface with the SCADA system’s alarm screen, which turns the pins from blue to red when the facility has an active alarm. This provides the field operators with visibility into operational issues near them.

The custom Alarm screen displays a Key Performance Indicators (KPI) dashboard that allows users to view all previously configured alarms and begin to standardize alarm schemas. TIGA created a relationship between field routes and Ignition Rosters to provide a low maintenance and efficient approach to notifications rosters alongside operational changes.

TIGA used the Power Chart to create global trending docks which allows the user to add and remove selected data from all screens. This capability permits users to trend across equipment within equipment, add notes, and export findings.

Using the XY Chart, TIGA built a Dynagraph Card viewer screen that lets users view all Controller Pump Off and On Cards. With this capability, operators are provided visual oversight to their oil field pumping conditions and can perform well shut ins if necessary.

TIGA integrated the client’s SCADA system with their Accounting System with an API solution using the Ignition Report Module and SQL Bridge Module. These modules created a unified integration between SCADA and Accounting, allowing jobs to automatically run without interfering with the real time data or Historian.

To provide robust and good quality data, a trusted OPC polling engine was required. After testing and weighing out multiple OPC engines, TIGA was able to integrate Autosol’s Communication Manager (ACM). Autosol engineers and developers worked alongside TIGA to develop drivers, patches and test to confirm every piece of data was validated and verified.

Value Delivered

TIGA helped the client achieve the goal of replacing a legacy SCADA System with a more extensible enterprise SCADA system using the Inductive Automation Ignition platform and one polling engine. TIGA worked to deploy perspective desktop and mobile screens that provide maximum overview visualization while also having the capability to deduct detailed information. Users are provided the ability to drill down from an area overview to a facility and maintain the selected facility while navigating through the rest of the SCADA platform. TIGA furnished flexible screens that scale throughout the platform providing users global functionality from their desktops or phones.

The customized platform has helped not only operations but enabled a digital transformation. TIGA was able to provide an interface for SCADA, the field, and business stakeholders to view and track the validation and verification processes for all operations and accounting from anywhere in real time.

TIGA continues to support the energy company’s SCADA System.