High Level Summary of Project

WaterBridge Operating, a midstream water management company was not receiving the level of reliability and support that they needed with their existing control and SCADA system. TIGA performed a phase one engineering assessment to determine the level of effort required to replace WaterBridge Operating’s control and SCADA systems to an updated IIOT platform. TIGA has an extensive track record in delivering integrated control and safety systems as well as deploying SCADA systems. Through the assessment TIGA was able to define a migration path to allow WaterBridge Operating to gain flexibility, consistent visibility into its operations, ownership of their control and SCADA systems, and cost savings over the life of the systems.

Problem

WaterBridge Operating had proprietary (closed) control and SCADA systems that were outdated and unable to meet the growth of its operations. WaterBridge Operating required a system that would allow them to better leverage emerging technologies in addition to gaining deeper insights into their operational data through an industry accepted Enterprise SCADA system and control system.

Within the last few years WaterBridge has experienced rapid growth during which time unreliability and stability issues within their control and SCADA systems became increasingly apparent. The system was unable to handle systematic changes that WaterBridge needed to run their operations at maximum efficiency. The cost of WaterBridge Operating’s solution was scaling dramatically due to not having direct ownership of their control and SCADA systems.

Solution

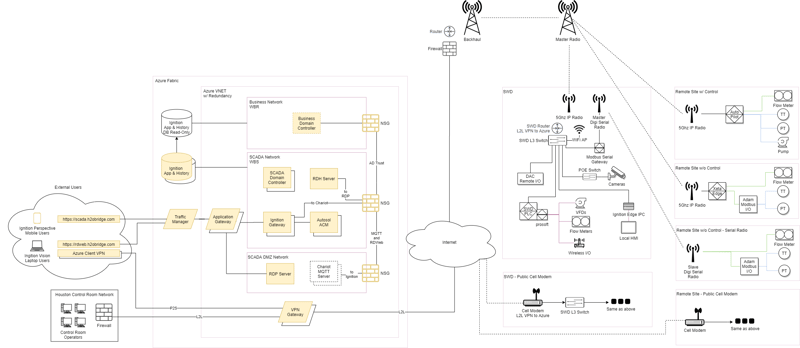

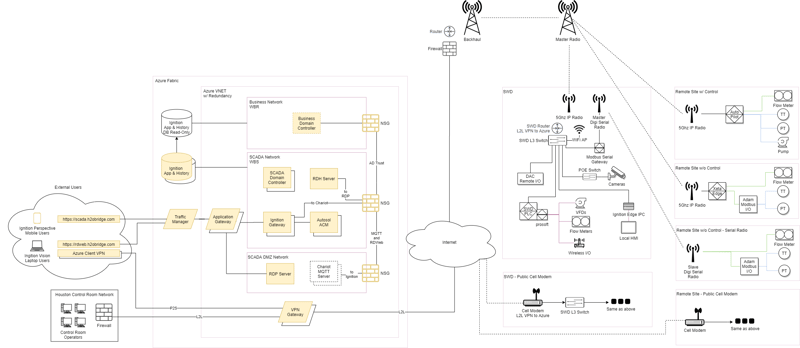

TIGA and WaterBridge worked together to architect a new design utilizing the latest industry standard PLCs and SCADA technologies. WaterBridge engaged TIGA to perform a functional assessment and design of a new SCADA and Control system. This assessment and functional design included utilizing Ignition in the Enterprise, Ignition Edge at each Facility, and Perspective as the user interface.

The Ignition SCADA platform enabled the use of Edge computing for the aggregation of data via Ignition Allen Bradley and Modbus OPC-UA drivers, the transport of high frequency data with optimized bandwidth usage via Cirrus Link’s, MQTT Ignition Modules, and the local visualization and control HMI with Ignition’s Edge Panel.

Following a successful pilot project, “Project Independence” was kicked off by WaterBridge Operating’s Charles Lame and TIGA to successfully replace the legacy proprietary field equipment and deploy Inductive Automation’s Ignition using MQTT and Sparkplug B at each Facility. TIGA’s implementation of the SCADA system focused on these core functions: Application Architecture, Ancillary and Data Integration

Sub Systems, UI/UX Design and Development, External Interfaces, and Local HMI uplift.

TIGA worked with WaterBridge Operating to deploy an Enterprise Ignition SCADA system within Microsoft Azure Cloud hosted infrastructure using Ignition’s Enterprise Application Module. The system was architected by utilizing MQTT and Sparkplug B with redundant Cirrus Link Chariot Brokers. This enabled WaterBridge Operating to realize a substantial increase in data resolution and data quality utilizing the Sparkplug B report by exception and store and forward.

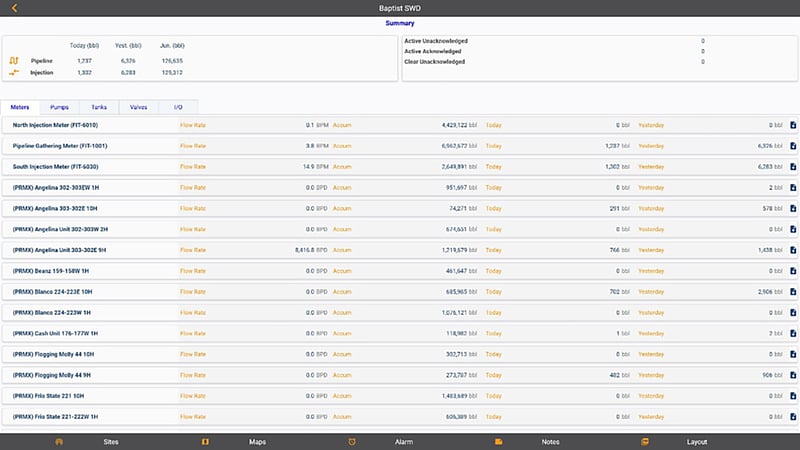

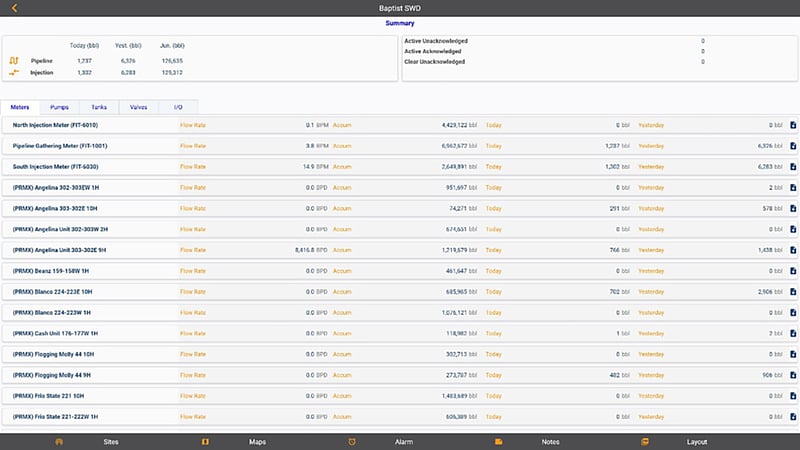

At each of the 65 Salt Water Disposal (SWD) facilities Ignition Edge with Allen Bradley, Modbus, and MQTT Transmission modules are being used for data collection. The system is collecting over two thousand tags at one second intervals per facility through this architecture.

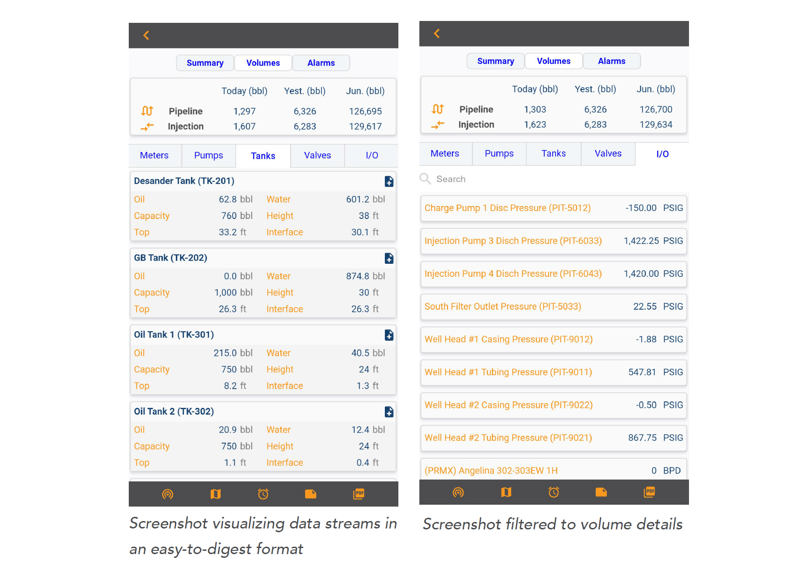

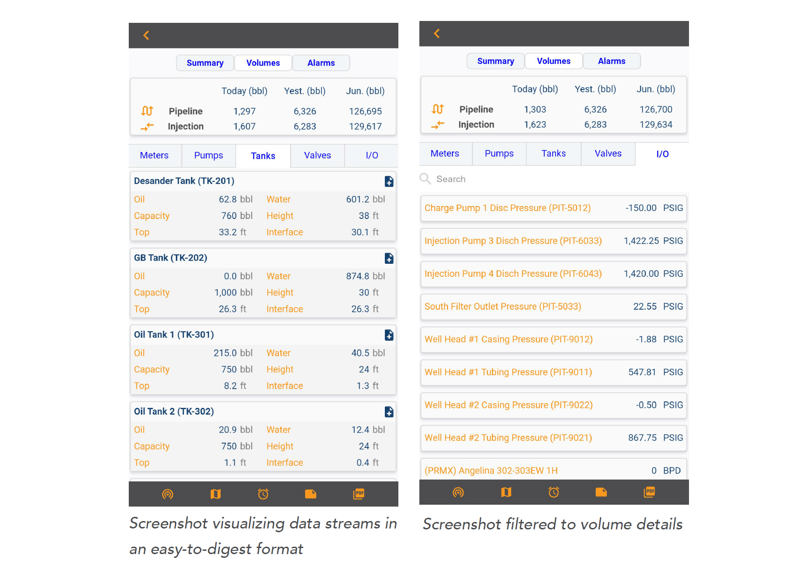

WaterBridge Operating and the TIGA team took a “Mobile First” approach to design and implement the visualization components of the Ignition Perspective System. This strategy of “mobile and content-first” allowed TIGA to workshop and sketch the Ignition Perspective UI and work towards the visualizations for all other User Experiences from mobile phones to high resolution monitors.

WaterBridge Operating and the TIGA team took a “Mobile First” approach to design and implement the visualization components of the Ignition Perspective System. This strategy of “mobile and content-first” allowed TIGA to workshop and sketch the Ignition Perspective UI and work towards the visualizations for all other User Experiences from mobile phones to high resolution monitors.

TIGA worked with WaterBridge Operating to repurpose the existing OnLogic IPC at each SWD facility and integrate Ignition Edge Panel for the local HMI. TIGA’s team developed a process to make the most current Texas RRC Lease and Drilling Permit data available for selection at the Edge devices used for Truck Unloading. Local HMI screens were developed to find and correct missing information on Truck Tickets created at those Edge devices. Using the corrected Truck Ticket information and Metered Piped volumes, TIGA developed a process to allocate Skim Oil Sales and report them on the Texas RRC P18 form. Ignition Edge Panel deployed at each SWD facility is centrally managed from the Enterprise Ignition System in Azure utilizing the Enterprise Application Module.

Result

This project allowed WaterBridge Operating and TIGA to implement an IIoT enabled Ignition SCADA System within a hosted Microsoft Azure infrastructure utilizing the Ignition Enterprise Application Module, Ignition Perspective for User Interface, Ignition Edge Panel and Edge MQTT with Cirrus Link’s Chariot Broker while maintaining control and safety systems at each location. This system enables a higher resolution of data, better user experience through Perspective, and a manageable open SCADA system.

By leveraging Ignition, TIGA was able to deliver a system that WaterBridge Operating needed in order to easily control their operations. Allowing WaterBridge Operating ownership of their control and SCADA systems has removed the need for the closed proprietary system. Operational processes are more efficient due to increased visibility for key stakeholders who can now make decisions in real time. WaterBridge’s Charles Lame stated that the cost of the previous SCADA system was a, “$200K a year known cost, but several million, due to equipment failures related to the program.” Centralizing the data has helped not only operations but has also enabled a digital transformation. The collection of data is stored in one location and serves over 30 WaterBridge Operating customers with the ability to monitor all aspects

of the midstream allocation.

The solution is made successful with the use of the following modules:

• Enterprise Application Module

• Perspective Module for SCADA Screens

• Ignition Edge Panel + Edge MQTT + Edge Enterprise

• Cirrus Link Chariot Broker

• MQTT Transmission, Engine, and Recorder Modules

• Autosol Communications Manager

WaterBridge Operating and the TIGA team took a “Mobile First” approach to design and implement the visualization components of the Ignition Perspective System. This strategy of “mobile and content-first” allowed TIGA to workshop and sketch the Ignition Perspective UI and work towards the visualizations for all other User Experiences from mobile phones to high resolution monitors.

WaterBridge Operating and the TIGA team took a “Mobile First” approach to design and implement the visualization components of the Ignition Perspective System. This strategy of “mobile and content-first” allowed TIGA to workshop and sketch the Ignition Perspective UI and work towards the visualizations for all other User Experiences from mobile phones to high resolution monitors.