Evolution of the Use of AVEVA PI

Traditionally, assets and metadata within AVEVA PI and AVEVA PI Asset Framework (AF) were primarily accessed by users through the platform or specific dashboards designed for PI integration.

With the expansion of digital oil field technology in the oil and gas sector, the complexity of data has grown, leading to an increased demand for advanced analytics. Data within PI is now needs to be interconnected with other systems, presenting new challenges such as:

-

- Asset changes affect multiple systems.

- Consistent and timely updates are required across all affected systems.

- Manual data entry is error-prone and costly.

Enterprise Cloud Data Solutions for AVEVA PI

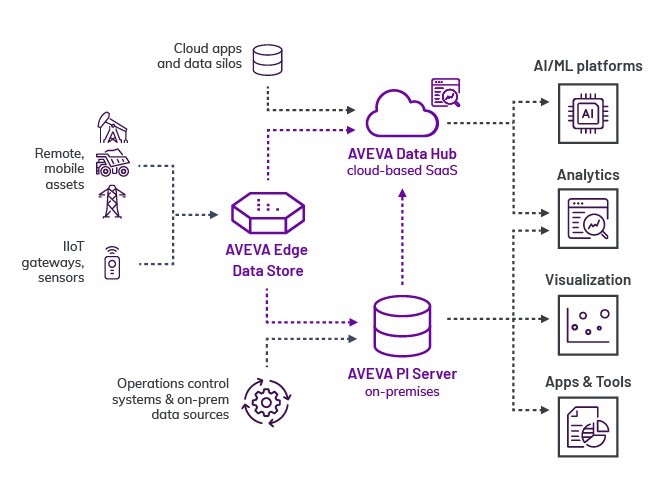

At TIGA, not only can we design, implement, and support AVEVA PI Systems, but we can architect an edge-to-cloud solution utilizing AVEVA’s PI System, which includes AVEVA Edge, AVEVA Edge Data Store, AVEVA PI Server, and AVEVA DataHub.

Our custom applications improve data quality and reduce effort by automating the creation of asset data across systems including fully automating both the PI tag creation process and the maintenance of multiple PI AF models.

Custom Application Example

Here is an example of a custom application we designed and implemented that reduced data entry and increased the efficiency of updating and maintaining various enterprise systems.

Challenge:

A major E&P company was challenged with significant data quality issues with their cloud-based enterprise dashboards. Data from multiple SCADA and enterprise systems were integrated to provide a more comprehensive view of operations.

These challenges included:

- When new wells were completed, the various enterprise systems were updated manually and at different times.

- Manual data entry led to many errors in the various systems.

- Each system was independent with no identifiers connecting the various systems.

These challenges led to significant data quality issues, requiring multiple teams to research and correct.

Systems:

- AVEVA System Platform

- PI System

- Plant Maintenance System

- Hydrocarbon Accounting

- Measurement System

Results:

The solution was to develop a web interface for the different enterprise system administrators to enter their data and utilize the PI System as the connection between systems by using the PI Asset Framework to hold the key identifiers for each system. This interface would then update each system and write the key identifiers to the PI Asset Framework.

Since multiple systems required the same data, this interface increased the data quality in each system by :

- Reducing manual data entry by 90%

- Reducing the time for the systems to be updated from 3-6 weeks to hours.

- Drastically reducing data entry errors

In addition, new key identifiers allowed the quick and easy connection of data from multiple systems allowing for easier and more accurate reporting, visualization, and integration.