Problem:

An energy company has an extensive asset base comprised of conventional and unconventional natural gas, natural gas liquids, and oil producing wells across the Appalachian Basin, as well as throughout the central and southern United States. As part of their efforts to move to a cloud-based SCADA system, they needed to get all operational SCADA data into the Microsoft Azure ecosystem.

Many of the solutions explored before talking to TIGA were predicted to take months of development, update at intervals instead of in real-time, and involved significantly greater investments in new software subscriptions.

Solution:

At TIGA, our developers work with SCADA systems every day. In collaborating with our clients, we saw the heavy lift it took to get data out of on-premise systems and into the cloud, where data could be better visualized, managed remotely, and made more secure. We developed the TIGA Cloud Connector as a tool to make it fast, efficient, and easy to connect operational technology data with business analytics and cloud platforms. Utilizing native OT system APIs and data integration ramps to pull data and send it to destination systems, TIGA Cloud Connector eliminates the need for complicated programming.

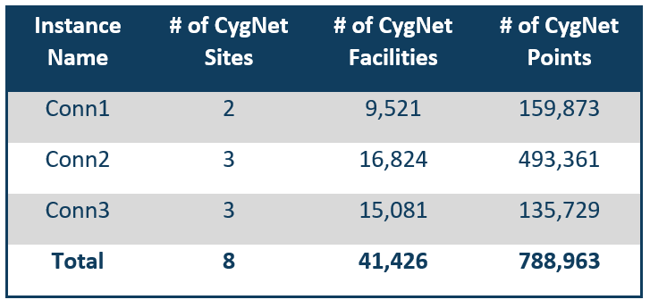

For this client, TIGA deployed three instances of our Connector Suite to integrate 8 CygNet Instances that contain 41,426 Facilities and 788,963 telemetered points with Microsoft Azure. The solution requires no other pieces of software. As data is collected from remote devices, that data is instantly accessible on the cloud. No lag time; no manual trigger required.

Publishing facility attribute and telemetered tag value/state changes in real-time enables the datalake to stay up to date with contextual data. The contextual data describes the type of facility/equipment, its use, operator routes, sensor readings, and more as data changes within the system. This methodology eliminated the need to run batch jobs on an interval.

In addition, our team uncovered other metadata issues in the Cygnet SCADA system that we corrected during the integration to ensure clean operational data was available.

Results:

Using the TIGA Cloud Connector, our developers conducted a quick setup and implementation where accurate, instantly updated data began streaming within a few hours. The energy company was also able to save more than 75% in development, integration, and testing costs. Maintenance on the TIGA Cloud Connector is very minimal and is typically managed by inhouse development teams which also keeps costs low.

With real-time operational data flowing, the energy company is now able to leverage the power of the Azure platform to perform data analytics, machine learning, and dashboarding. The data stream is also now integrated from Azure to Graphana for further visualization. The additional tools make it easier to identify problems within the systems, optimize production, and offer greater insights into operations as a whole.

Our client is currently preparing to implement more instances of the TIGA Cloud Connector. The solution is easily scalable, and each instance only requires the same minimal set-up and implementation.

Learn more about the TIGA Connector Suite,