Problem

The University of Oklahoma (OU) Norman Campus is a large campus made up of over 300 buildings distributed across a sprawling 3,326 acres. Using equipment from various manufacturers, OU’s district energy infrastructure is comprised of four chilled water plants and two steam plants supplying reliable electric distribution, chilled water, and steam through 72+ miles of piping and cabling.

For the past decade an outsourced company has operated and maintained OU’s utilities. Through multiple Engineering, Procurement and Construction (EPC) led projects, the company performed at point repairs and asset specific upgrades that ensured continuous and

reliable operation though lacked an in-depth approach on how to integrate the different assets into a cohesive system. To gain greater control of their utilities and the systems supporting them, OU ended the outsourcing arrangement and brought the utility services in-house. With much of the utility infrastructure having been built and installed in the 40’s and 50’s or constructed during ownership transition, there was minimal documentation regarding what equipment was installed, nor engineering documentation on how the system was connected.

As part of a strategic plan to bring all of OU Utilities into comprehensive integrated platform, TIGA was consulted to inventory the current control system and provide recommendations to improve efficiencies, reliability, and safety. As system experts, TIGA contributed a path for creating a more comprehensive and responsive control system to better manage the complexity of utilities on a large campus.

The largest issue facing OU’s Utilities team is the utilization of many outdated SCADA systems in multiple plants that were in some cases improperly implemented. This has contributed to a congested and complex control room monitoring process, ultimately limiting the operator’s ability to quickly respond to issues.

Solution

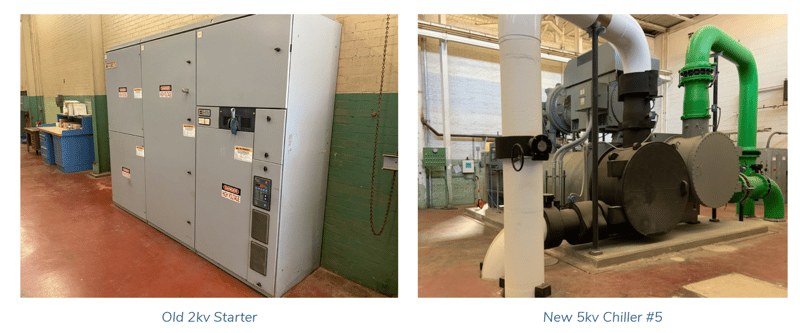

The key objective of this project was to unify the SCADA system and provide the OU team a more efficient operating platform for system monitoring, maintenance performance and implementation of planned improvements such as adding new chillers and plants.

Using the AVEVATM System Platform, TIGA consolidated much of the University’s district energy systems into one reliable, flexible, and comprehensive control system built specifically for OU’s unique combination of equipment and infrastructure. TIGA performed the entire SCADA integration including hardware, software, data aggregation, and analytics. In addition, TIGA engineers developed custom software to allow secure remote access into the control system from anywhere.

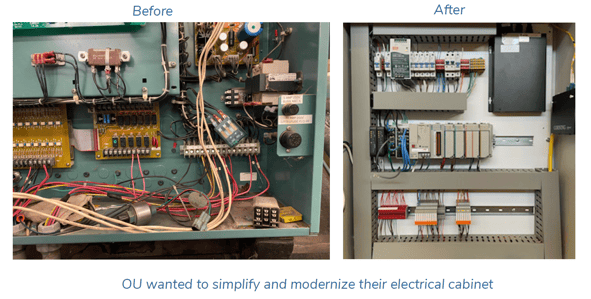

To enhance efficiency, TIGA replaced the existing electrical cabinets with new Allen-BradleyTM ControlLogix® processors, redundant Ethernet I/P infrastructure, and stainless cabinets to provide a safe and reliable control system.

As part of OU’s strategic plan for system integration, the University’s oldest boiler plant, containing three high pressure industrial boilers, was earmarked for a significant two-part boiler controls upgrade.

In the summer of 2021, the first part of the project was initiated to bring the 120,000 lbm/hr boiler’s Burner Management System (BMS) controls up to newest NFPA 85 rules and standards.

TIGA and an OU assigned contractor are implementing HoneywellTM BMS and ControlLogix CCS controllers. Part one of the project is expected to complete in fall of 2021. Part two, which contains the remaining two 60,000 lbm/hr boiler, will be performed in 2024. This will be one of the largest controls integration upgrades to date for the University.

In addition, the existing antiquated SCADA system for the distribution portion of district energy did not provide visibility of key pressures and temperatures for medium pressure steam and chilled water, through the campus footprint. This information is critical to operation of and respond to the utilities system. To provide this visibility, TIGA installed Rosemount transmitters, Phoenix Contact ethernet switches, and the AVEVATM SCADA to give enhanced control of loading.

Finally, with the integration of AVEVATM Historian Insight, TIGA created the ability for OU to quickly identify equipment failures, storyboarding failures for later analysis, and supervising controllers in how they operate the plants to better equip them in future training scenarios.

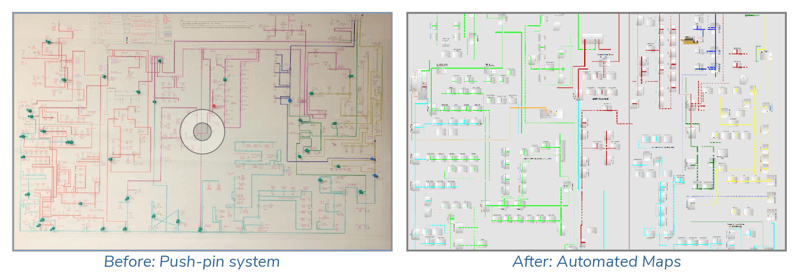

Power Systems Visualization

One of the more unique components to TIGA’s solution was the development of a web-based electrical distribution map. At project onset, OU had very limited control or visualization of their power distribution system due to automated parts being controlled by obsolete or antiqued controls. TIGA provided a fully animated power distribution board, incorporating the automated portions where applicable, using AVEVA System Platform and IntouchTM OMI. In addition, TIGA developed custom notification software to allow real time monitoring, control, and notification of the entire power system on campus. This new technology replaces an outdated system of AutoCAD printouts and colored pushpins.

The map details every major electrical distribution line on the campus and is automated to show lines with and without power. If a line does not have power the team can close switches to regain power to a building or group of buildings. This allows for testing of complex switching operations prior to actual configuration changes, ensuring anomalies and issues were identified and addressed upfront. Outage duration, resultant of on campus issues, were significantly reduced through use of the new system. Rapid notification helped improve response time. System troubleshooting can now be resolved in seconds through a series of automations and notifications.

Results

“TIGA provided and continues to support the University of Oklahoma Utilities with a cutting-edge SCADA platform that allows us to visualize our electrical, chilled water, and steam distribution throughout the entire campus and respond to failures at a moment’s notice improving reliability and safety throughout.” Jeremy Debaets, Director of Utilities

Improved visibility and controls

OU gained a new level of responsiveness through the remote monitoring and control provided by the AVEVATM platform. Their system is now easily scalable to include many thousand I/O points and assets. The team has significantly increased visibility to utility assets at the university. In addition, remote controls allow for more flexibility and centralized support across the campus.

Reliable support

TIGA delivers around-the-clock software and hardware support to the OU Campus. If any issues are detected within their control system, TIGA can perform immediate remote maintenance or timely on-site repair depending on the issue. Beyond bug fixes and hardware replacements, support provided includes new additions to the system as well as enhancements. Through the continued improvements to OU SCADA system, TIGA has helped to significantly reduce operation and maintenance costs to the university.

Predictive analytics engine and cost savings

Corrective maintenance was one of the largest line items in the operations and maintenance budget. As a result of the improved process controls and SCADA systems, increased analytics now help quickly identify equipment failure, understanding and predicting system wide impacts. With the ability to reference historical data and implement actions to prevent future failures, corrective costs continue to decrease and scope of repairs is more localized and specific. This has resulted in better uptime and greater system reliability.

With near future large scale utility investments at OU’s Health Sciences and Tulsa campuses, the Utility Department is working to articulate the criticality of incorporating the necessary investments into an integrated and cohesive operating system, similar to what TIGA is helping the University accomplish at the Norman Campus.